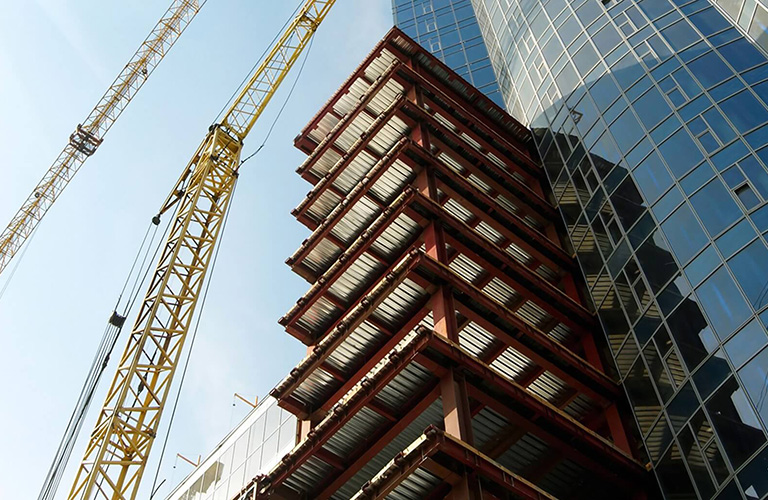

The parts are formed by pre-assembling and assembling.

![]()

What is Prefabricated?

The parts are formed by pre-assembling and assembling.

Prefabricated Housing

Housing constructed on walls, doors, windows and other elements fabricated and mounted on a concrete platform to be built.

Prefabricated; The prefabricated word is not a word in Turkish but it has come to us in English. This is the original "prefabricate", or "prepare the pieces in advance".

Prefabricated; parts are made in factories and are assemblies where these parts are transported and assembled after assembling the parts as previously planned. With prefabricated it is possible to build single storey or multi storey constructions.

With the prefabricated structures that can be used in houses, social facilities, schools, construction sites, hospitals, camping areas, pools and public areas can be uncovered.

Advantages of prefabricated structures Advantages of features

On-site manufacturing is long and laborious and labor costs are much higher. If the work is fabricated, the quality of the reinforcement and concrete will increase. economical. Many mold materials are replaced by hundreds of products in a single mold, which greatly reduces the cost of molds. It provides the benefit of the time, which in turn shortens the work to completion. By using air compression technology it increases the density by increasing the density of the concrete. In this method, it reduces the water absorption rate of the concrete, more benefits than ever before.

Because the prefabricated buildings are modular, they can be planned and produced according to needs

Prefabricated structures are much more practical than other constructions and can be delivered in much shorter time

Prefabricated structures are more flexible than other structures and they are resistant to earthquakes

Prefabricated structures can respond to every request

Prefabricated rooms, balconies, bathrooms can be placed in desired places

Prefabricated buildings have much more heat and sound insulation than other constructions

Production according to all kinds of area and size

Optionally have viewable options

Removing or modifying parts that are unwanted or need to be replaced

Creation of the environment without pollution and disturbance

Foundation without foundation, installation on grobeton laid for single-storey structures and installation on foundation for multi-storey structures

Possibility of recognizing the rich possibilities of prefabricated buildings, roofing materials and wall covering materials, from the raw material properties to the coloring, optionally

Prefabricated; trapeze hair, single and tile varieties available

To be able to provide diversity in interior and exterior walls of prefabricated structures such as fibercement, PVC, yalı printing, plastered mantle and biscuit brick.

How long is the life of prefabricated houses?

The life of prefabricated houses varies from at least 40 to 70 years. When we think of prefabricated buildings, we usually think of our people as the earthquake house. But prefabricated constructions are designed and manufactured so that they can be used both in summer and winter, whichever technique is produced.

According to the material and technique used for prefabric construction, we can lay a minimum life of 40-70 years. Prefabricated steel, cement chipboard (betopan-fiberciment) is used. Sound and heat insulation is projected.